Sigurd Kloumann.

Sigurd Kloumann

Sigurd Kloumann ties together the establishment of Norsk Hydro in 1905, the investment in aluminum in Høyanger in 1915 and the development of a further processing industry in Holmestrand in 1919.

Kloumann was an engineer and had the main responsibility for Hydro's development projects at both Notodden and Rjukan. He felt like Hydro's founder, Sam Eyde, was getting all the credit, and decided to leave Telemark and Hydro to become to pursue his own company. Together with key figures from the establishment of Norsk Hydro and a group of scientists and investors, he founded the all Norwegian company A/S Høyangfaldene in 1915. It was the start of a Norwegian industrial adventure that would have global significance.

- 1/2

Høyanger 1916. - 2/2

Høyanger around 1930.

The newly formed A/S Høyangfaldene aimed to master all stages of aluminum production, ie everything from bauxite mines and oxide production to metal production and further processing of products.

For a long time, the worldwide aluminum cartel, which consisted of companies that had secured patents in the early beginnings of the industry, controlled the supply of markets, production, prices and raw materials. But when these patents expired, the scene was set for the all Norwegian venture.

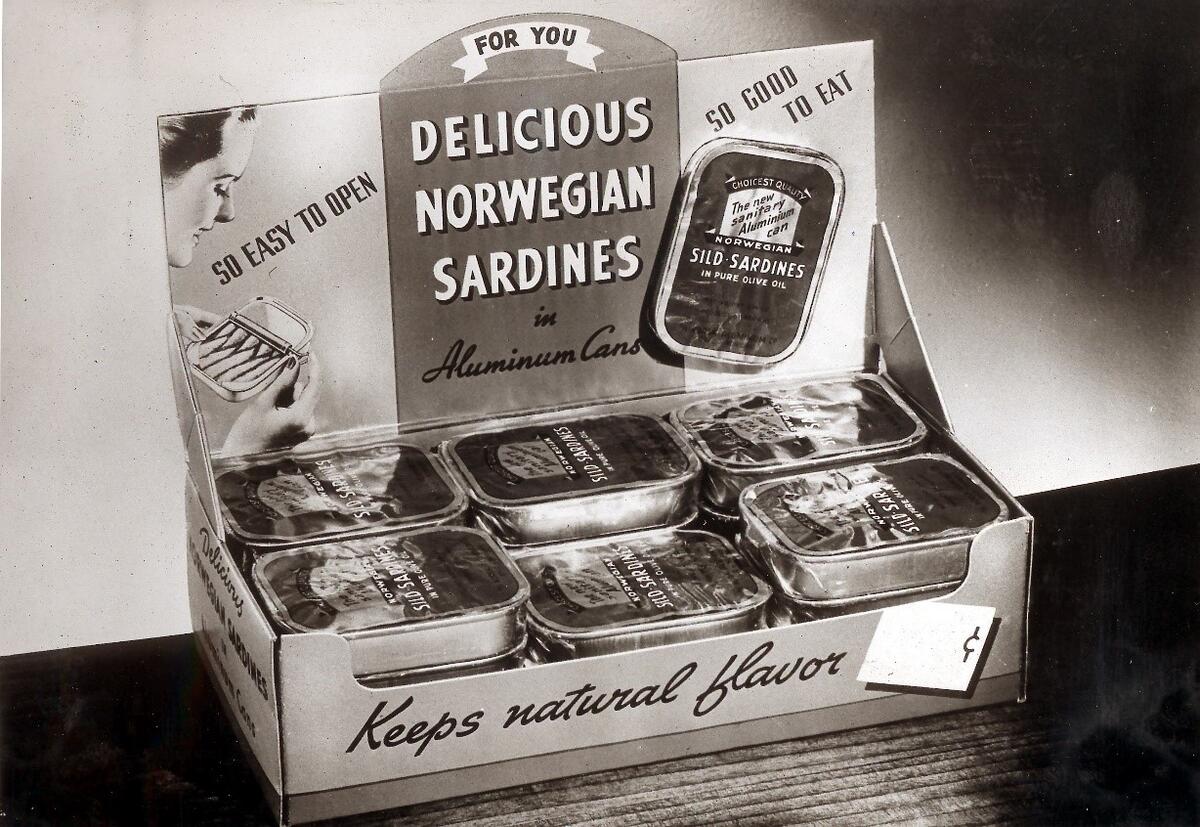

While ambitions to secure bauxite deposits in France had to be abandoned, an oxide plant was set up in Høyanger. The metal from this was to be further processed in Norway, and at the turn of the year 1917/18, the subsidiary A/S Nordisk Aluminiumindustri was established in Stavanger to produce aluminum strips and cans for the canning industry.

At this time, the canning industry was one of the country's largest industries, and the goal was for aluminum packaging to replace tin cans. But it soon became apparent that the metal reacted chemically with the contents and the boxes started to bulge.

Packing and preparing sardines.

A problem solved

Why the content expanded and the boxes swelled, nobody knew. The company was determined to solve the problem, but lacked expertise and the specialist community in Norway was small. But A/S Sveiseverket in Holmestrand was an exception.

They had a sole license in Norway to weld aluminum, extensive experience in metalworking and their own research laboratory. In 1919, the two companies signed a cooperation agreement, and Nordisk was moved from Stavanger to Holmestrand. In addition to competent workforce, Holmestrand was able to offer an expanded road and rail network, good port conditions and proximity to the markets.

- 1/1

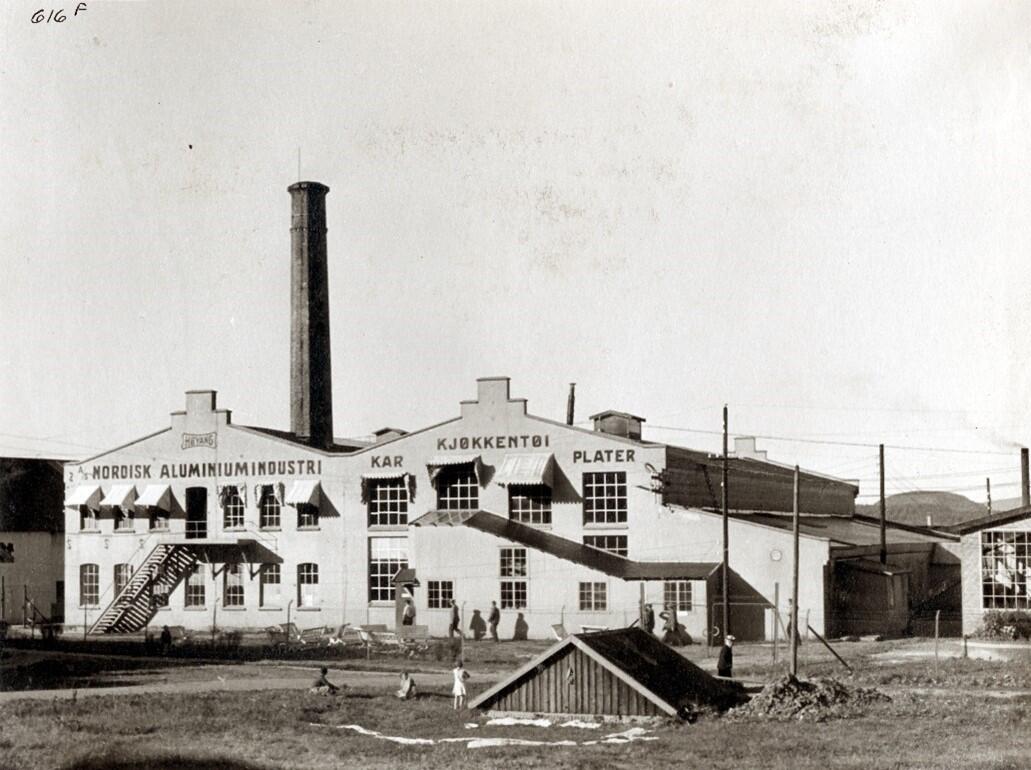

A/S Nordisk Aluminiumindustri in Holmestrand in the 1920s.

In 1919, aluminum was a relatively unknown metal with few areas of use. Naco therefore had a clear goal of expanding its use while at the same time trying to solve what was referred to as the "canned matter". The initiative helped make Nordisk one of the country's most advanced industrial communities, and the only aluminum producer that produced both intermediate and finished products.

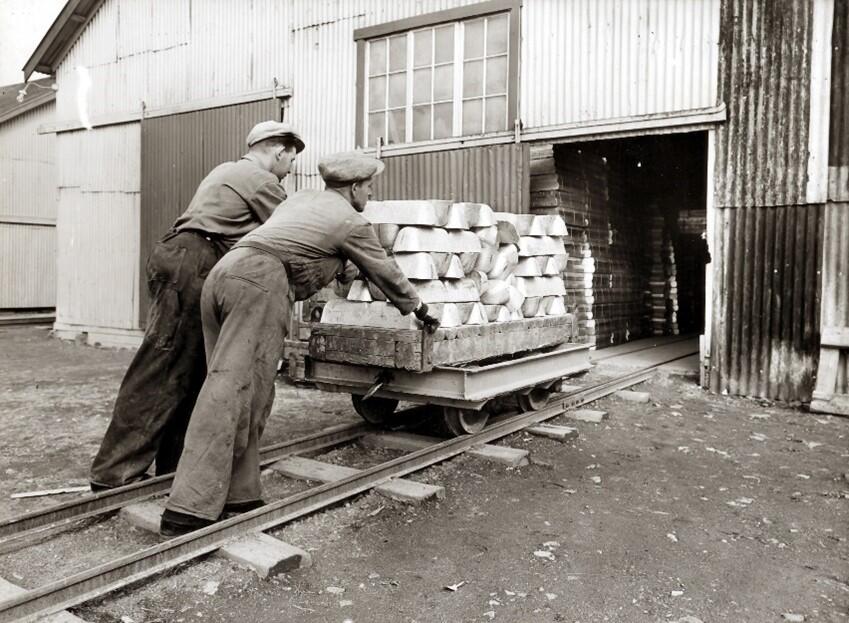

In the foundry in Holmestrand, aluminum from Høyanger was cast to roll blocks.

- 1/1

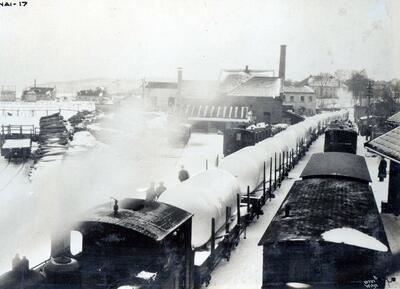

Transport of ingots (aluminum bars) from Høyanger to a warehouse in Holmestrand. Ingots were transported by sea from Høyanger.

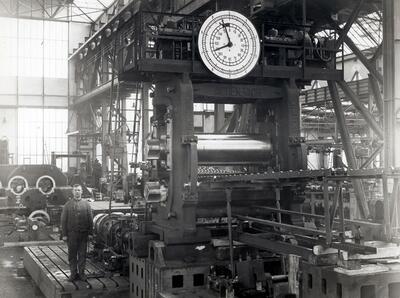

In the rolling mill, the roller blocks were processed into semi-finished products in the form of plates for the transport industry, for kitchenware production and eventually also strips to the canning industry.

- 1/2

From the rolling mill in 1931. - 2/2

Block foundry 1937.

- 1/4

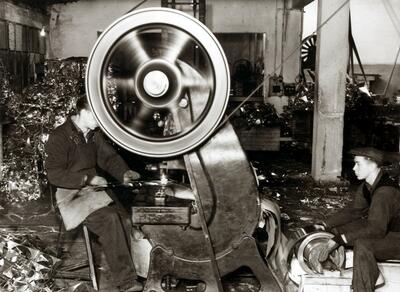

Manufacture of canned packaging in the 1930s. - 2/4

Vestfoldmuseene IKS: Drop-forging. - 3/4

- 4/4

Oslo Tramways with a bus produced by plates from Nordisk in 1935.

In Holmestrand, a wire drawing plant for electric cables was also installed and it focused on the production of finished product of crockery, milk buckets, large tanks for dairies, breweries, chemical factories and petroleum transport.

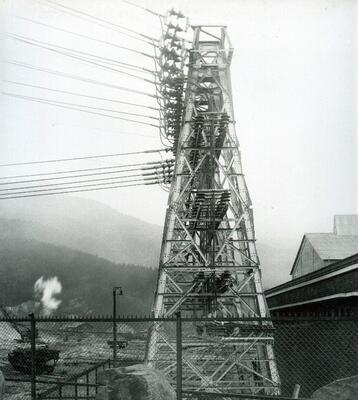

- 1/4

Sauda cable mast. - 2/4

Tank containers on its way from Holmestrand to Trondhjems Aktiebryggeri in 1923. - 3/4

Transport of petroleum in a tank from Nordisk in the 1930s. - 4/4

Advertisement for milk buckets in a car with aluminum bodywork in the 1930s

The launching of Høyang

The brand Høyang was launched already in 1921. Kitchenware labeled Høyang was more or less the face of the company, and during the interwar period there was hardly a home in Norway that did not have a Høyang saucepan. The largest competitor was the company IL-O-Van Aluminiumvarefabrikk A S in Moss.

- 1/1

Excerpt from a kitchen display in Drammen in 1931.

After the First World War, the economic situation in Norway was very difficult. Everything was costly and Naco was in dire need of capital. In 1923, the American company Alcoa came became one of the owners, and the A/S Høyangfaldene changed its name to Norsk Aluminium Company (Naco). The new owners secured the majority of the ownership and wanted to prioritize raw material production in Høyanger. Thus, the factory in Holmestrand received little interest for its desire to invest in canned materials.

But when the Canadian company Alcan took over the shareholding in Alcoa in 1928, it marked a change in strategy. The companies split the market between them, and Naco gained a monopoly on the Scandinavian market. The new owners were also far more interested in further processing, which among other things facilitated a long-awaited breakthrough in canning research.

- 1/2

From the anodizing department in 1935. - 2/2

The anodizing tub.

In Norway, there was still great skepticism about the anodized aluminum boxes, but they were a great success in the export market and were very well received in the US and England.

- 1/1

Sardines in anodized aluminum boxes packed and ready for sale in England and the United States.

Norwegian aluminium canning abroad

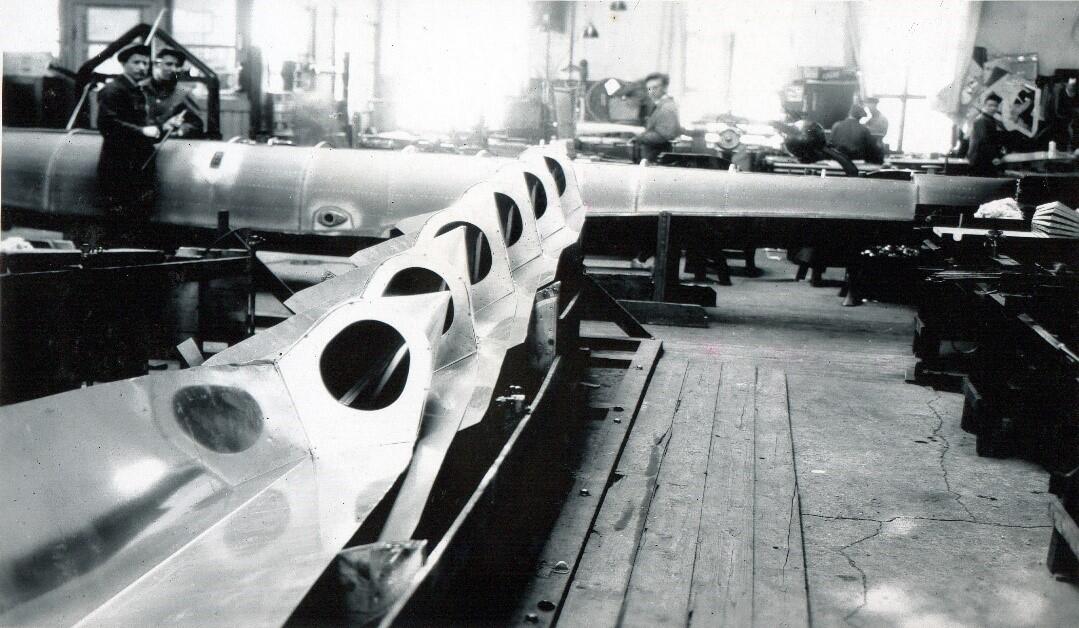

The breakthrough was a result of the canning and aluminum industry's push to market Norwegian aluminum canning abroad. This contributed to a strong increase in the production of strips for the canning industry and further investment in intermediate products. The new production process also laid the foundation for the production of plates for trams, trains, boats and aircraft, as well as large tanks for various purposes.

- 1/1

The Navy’s flying boat factory in Horten in the 1930s.