The state as an employer

In 1967, a new chapter began for the Norwegian Aluminum Company (Naco) and its subsidiary Nordic Aluminum Industry. The company became part of the state-owned Årdal and Sunndal Verk (ÅSV). Internationally, more and more companies controlled all parts of the production from mining to finished goods, but ÅSV did not have this opportunity. Through the merger with Naco, ÅSV gained access to both oxide in Høyanger and further processing in Holmestrand. Since Naco got bauxite through its Alcan shareholder, they were able to produce oxide for their own consumption.

Under ÅSV, Nordisk developed into a head office for research and development in the field of aluminum processing, and the company acquired several processing plants in Norway, Sweden and Denmark. Nordic took the initiative to form the Nordic collaboration body Skanaluminium, which was to run general product and market development. In connection with the Nordic collaboration, aluminum consumption in a number of countries was surveyed, and the survey showed that Norway was ahead of its neighbors in terms of packaging and crockery, but was behind on transport and construction. Therefore, production in Holmestrand became more concentrated on intermediate products and the development of new products. Many production lines were moved to other parts of the comprehensive ÅSV system. The traditional kitchenware production was moved to Il-O-Van Moss, which was acquired by Nordisk and was thus also part of ÅSV. What was left in Holmestrand of the old "kitchenware" were mainly products for large-scale kitchens and milk buckets. Instead, production concentrated on roll-bonds for refrigerators and freezers, car parts, special products for the transport sector and materials for the construction industry.

In 1969 there was a technological breakthrough in research in materials for building construction. In this connection, Nordic built eight aluminum houses in Holmestrand, which received a great deal of attention.

- 1/1

Photo: Eiendomsmegler1.

As a result, the capacity of lacquered tapes was expanded, and the company's lacquer facility could thus provide panels for the building industry with a larger color range and different surface treatments. In 1972, and in the second half of the 1970s further emphasis was placed on materials of this kind as well as strips for the canning industry. In 1974, canned food products proved to be a highly profitable, and thus the main strategy was to invest in the processing of canned and building materials.

However, the production effort did not quite meet expectations. Canned food faced competition from the food freezing technology, and building materials suffered a severe scratch in the paintwork, figuratively, during the transition to the 1980s. The top layer of lacquer was not adapted to Nordic conditions, and passed through too much sunlight that destroyed the underlying primer layer. The paint peeled off and revealed visible white spots. Claims for compensation became a costly affair for Nordisk, especially since the aluminum market was increasingly characterized by low demand and declining prices throughout the 1970s.

- 1/1

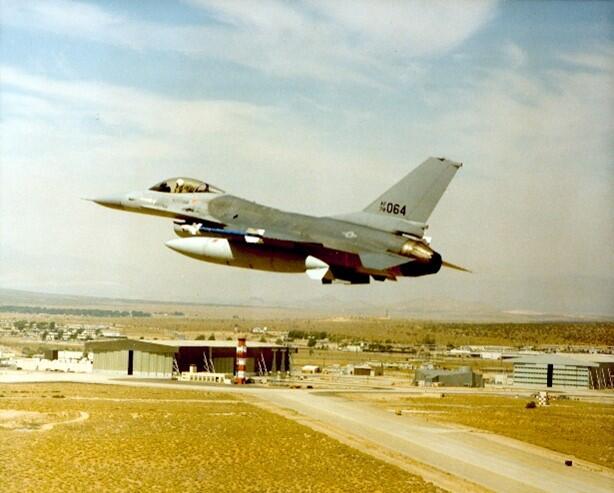

F16 with drop tank from Nordisk Aviation Products.

The transition to the 1980s presented challenges in several areas. By 1979, the state had gained full control of ÅSV. This meant that Nordisk lost its contact with the international research community in the Alcan system, which the company had been a part of since 1945. Now the research was continued in collaboration with Norwegian communities, including NTNU and Sintef, and even more concentrated on alloys and production in the rolling mill.

Thus, production was further concentrated on intermediate products rather than finished goods, and several production lines were relocated during the 1960s and 1970s. Wires and ropes, which had been produced in Holmestrand since the beginning in 1919, were moved to Årdal, road safety equipment and acoustic ceilings for Vik in Sogn, in Høyanger Fundo took over the rim production for Saab, Volvo, Volkswagen and Porsche, to name a few.

- 1/1

ÅSV + Norsk Hydro = strong alloy. Photo: Norsk Hydro.

Another area that Nordisk positioned for was equipment for military and civilian aircraft. The production of air cargo containers and the highly technologically advanced production of drop tanks, external fuel tanks, for F-16 fighter jets, became a success for Nordisk, and is perhaps the foremost expression of the fact that Nordisk developed its skills and abilities even after being disconnected from the research communities in Alcan.

During the transition to the 1980s, aluminum prices decreased, and although the economic situation gradually improved, the situation was very difficult for the Norwegian aluminum industry for a long time. From an industrial policy point of view, many wanted some form of cooperation or merger between ÅSV and the aluminum business of Norsk Hydro. Hydro, in collaboration with the American company Harvey Aluminum, established the company Alnor in 1963. Alnor started aluminum production and further processing at Karmøy, and shared the Norwegian market with ÅSV. It was believed that a merger between the two companies would create a unit that was less sensitive to cyclical fluctuations. Negotiations began in 1985 and in 1986 the merger was realised. A new chapter for Nordisk could begin.